Quality assurance in module production

CIT-type quality assurance tools are used in several stages in module production. At each point, they are equipped according to their application. A typical example is the production of electronic modules with multiple silicon dies. During removal from the sawed wafer, the system inspects for potential damage. Once the module is loaded, the CIT automatically checks for correct layout, soldering quality and other QA criteria. In a subsequent assessment, we use deep learning/machine learning algorithms based on artificial intelligence.

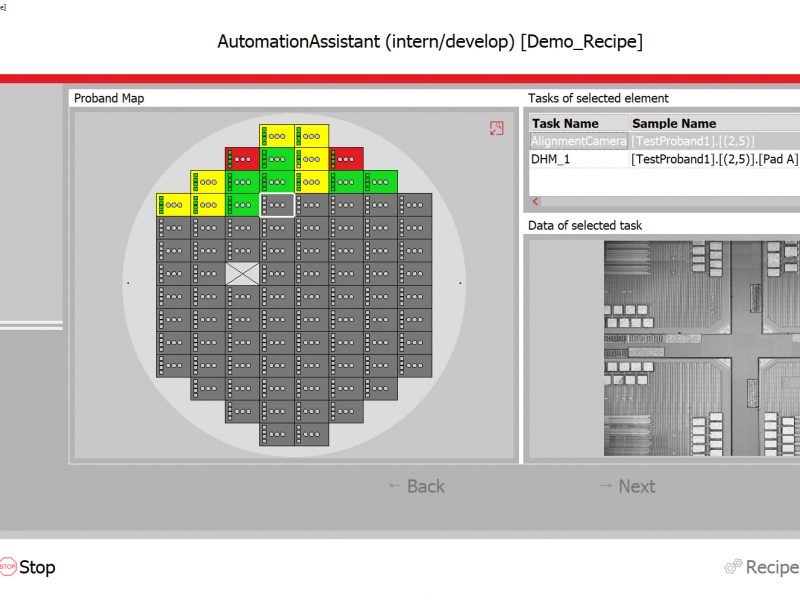

Innovative optical systems

In order to achieve the best result for you, we work with experts in camera technology and pattern recognition. Our tools combine complex positioning of the devices to be assessed with highly innovative optical imaging systems. The Automation Assistant software makes it easy to create recipes and set up the various wafers and test structures. It controls the measurement systems, collects the data and assesses it. Any defective or deviating structures are highlighted.

The benefits for you

- Fully integrated autoprober system with wafer loader and pattern recognition system

- One piece of software responsible for full system control, recipe creation, wafer mapping, analysis and data export

- Detailed analyses of the assessed structures, with µm resolution

- Deep learning/machine learning for assessing the functional suitability of the structures